Welcome to the brake caliper specialist!

NB PARTS (New Brake Parts) has established itself as a specialist in the caliper industry. Our aim is to delight our customers with our companies (unique) feature of setting new standards concerning products and services as well as its exceptional corporate philosophy. These standards concern all fields of action – from the continuous improvement of our processes to the awareness of our social and ecological responsibility.

Individual products need individual solutions. Together with our customers, we individually develop products that implement the required properties.

Cost-effective, flexible, in large or small series.

Our advantage over our competitors

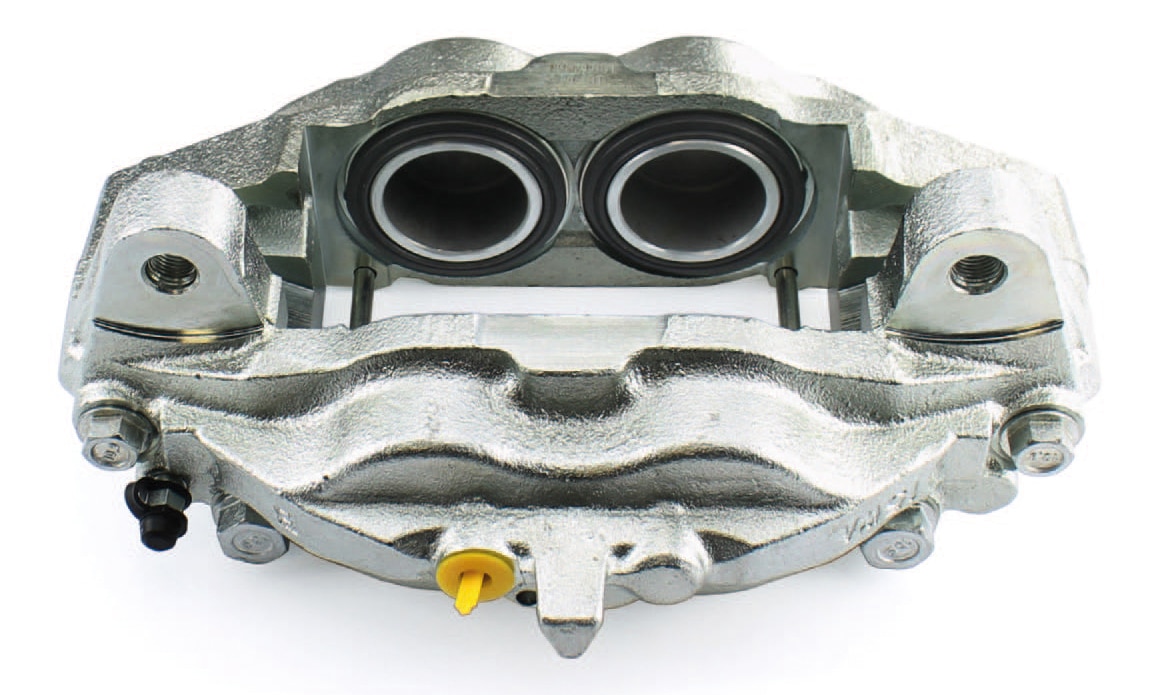

NEW PARTS IN OE – QUALITY

Our calipers are manufactured according to OE directives. Each brake caliper is subjected to a 100% low & high pressure test before delivery. We use only new parts as housing and no refurbished used parts with traces of usage.

NO DESPOSIT REQUIRED

Your old parts are not needed since we only use new parts. Your benefits: no costs for returns, no use of accounting and no monitoring of credits.

INCL. EQUIPMENT

The guide sleeve sets belong to the scope of delivery as well as the accessories of the brake pads. This allows your customers a smooth installation.

PRIVATE LABEL

Private labels strengthen YOUR position in the market and enable to achieve an increase of profit margins. That’s why we offer you the Service “Private Label Packaging” including the installation instructions.

NO MINIMUM PURCHASE QUANTITY

You can order our entire range at any time and without minimum purchase quantities. By request, we also manufacture brake calipers individually according to OE directives without minimum order quantity.

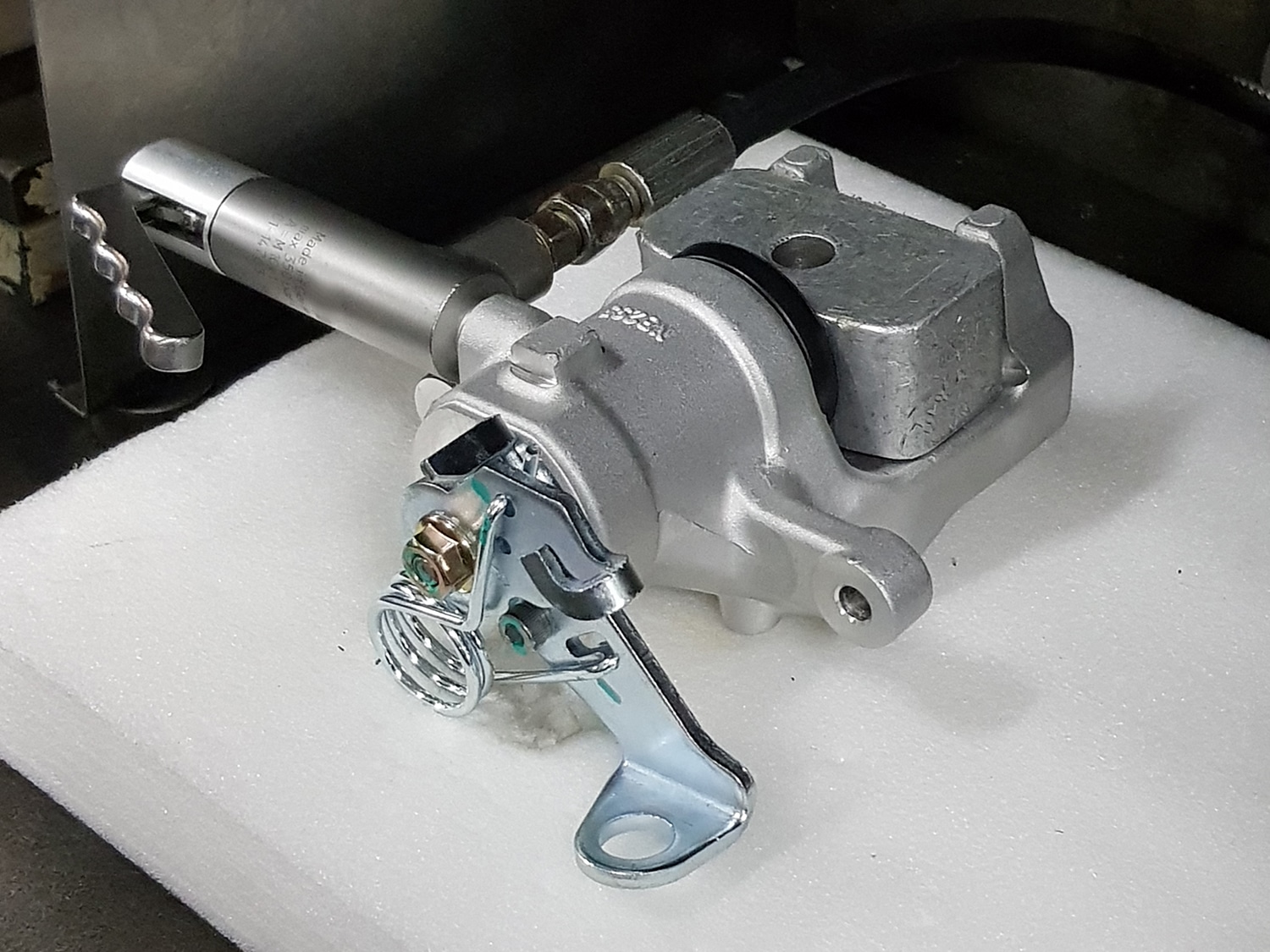

These calipers can be delivered with a caliper bracket and accessories.

By request, we assemble the complete set including the disc brake pad.

These calipers can be delivered with a caliper bracket and accessories.

By request, we assemble the complete set including the disc brake pad.

Continuous quality management ensures product safety

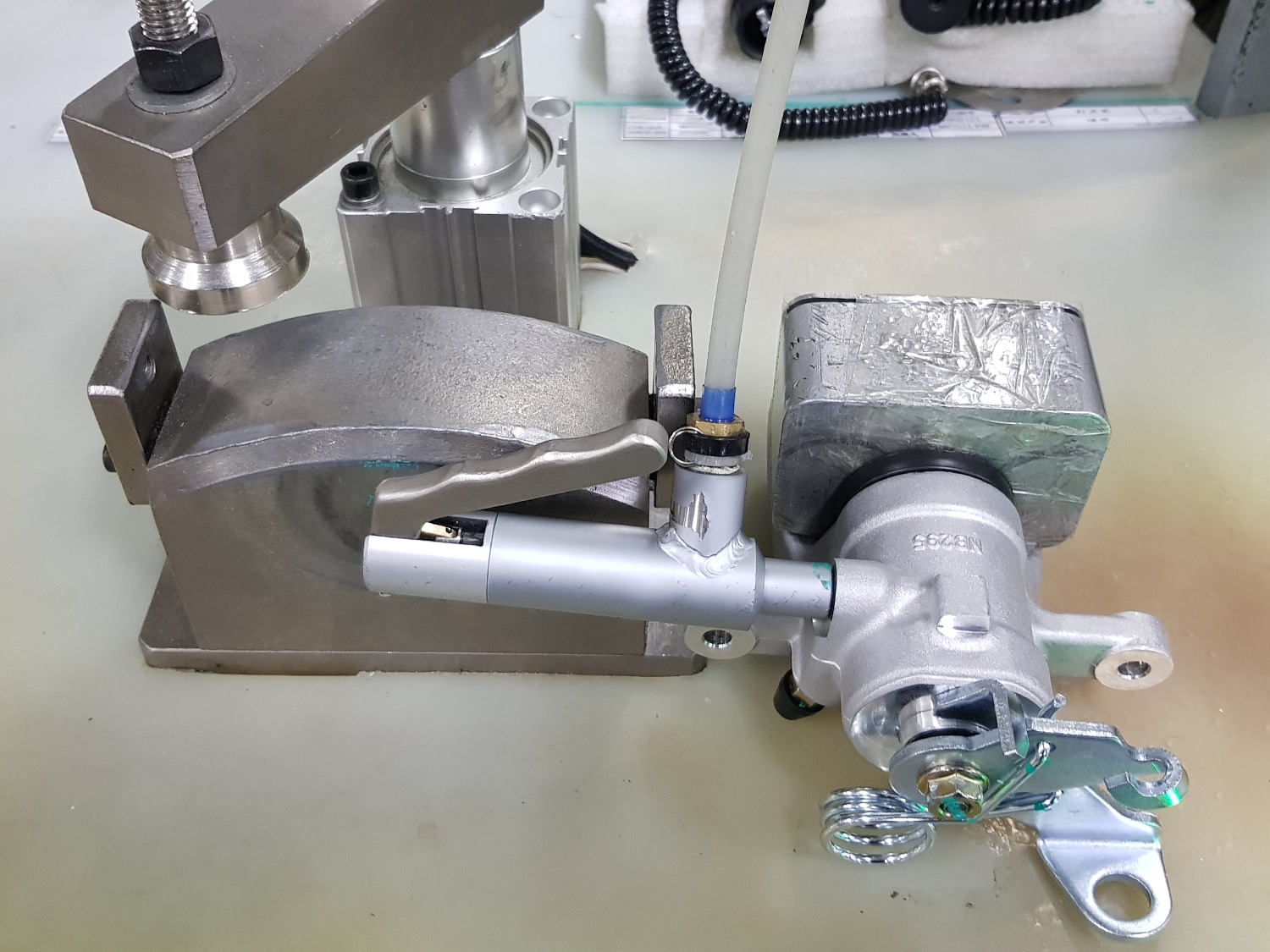

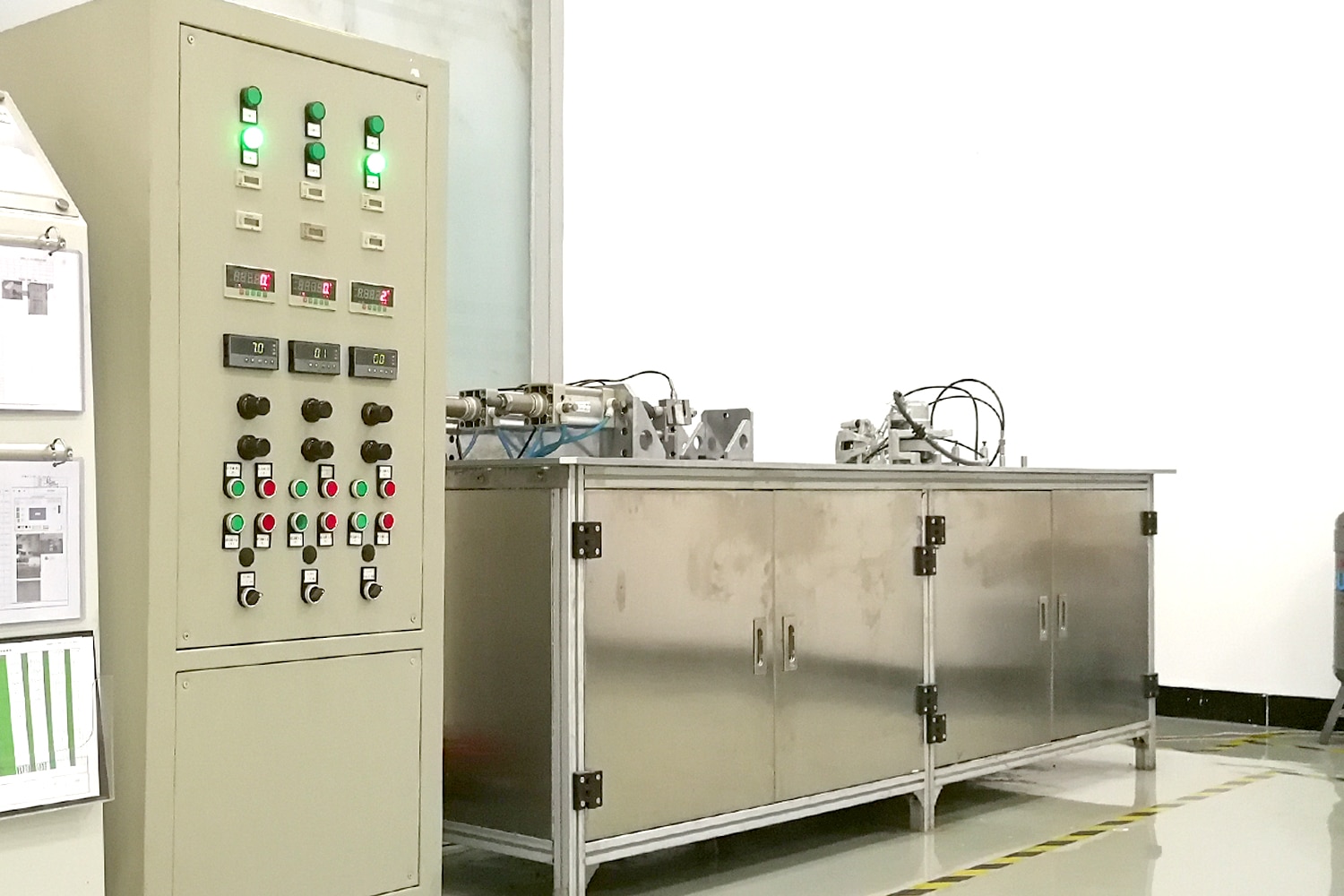

Testing of all calipers in the high-pressure range

At a pressure of 50 and 100 bar, the brake calipers are testet via a pedal lock. Over a period of 10 minutes, the set pressure may not fall under a 10% range.

Testing of all calipers in the low pressure range

The calipers are connected to a low and high pressure manometer and tested with a pedal lock while resisting at least 5 minutes under a pressure of 5 bars.

Safety relevant

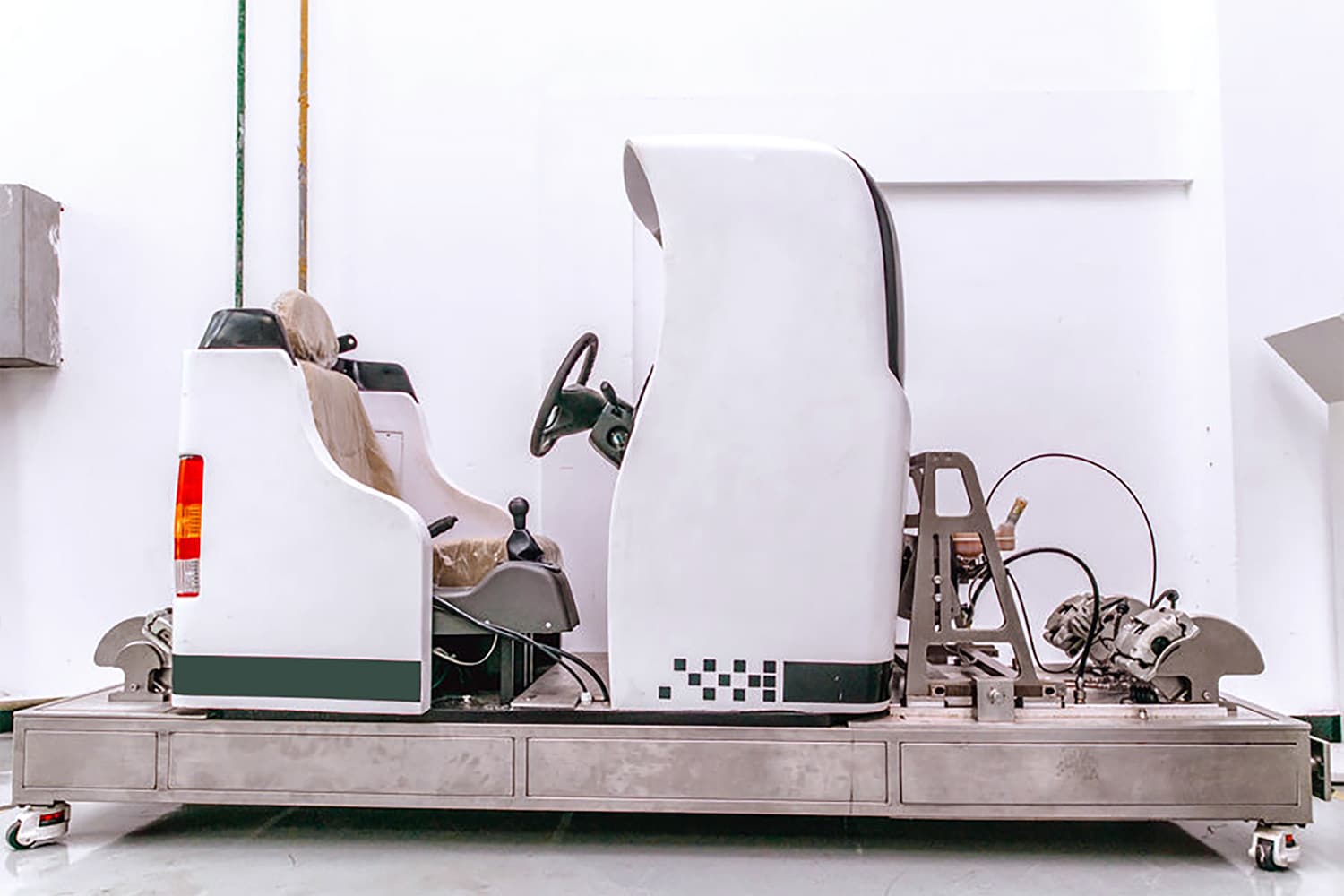

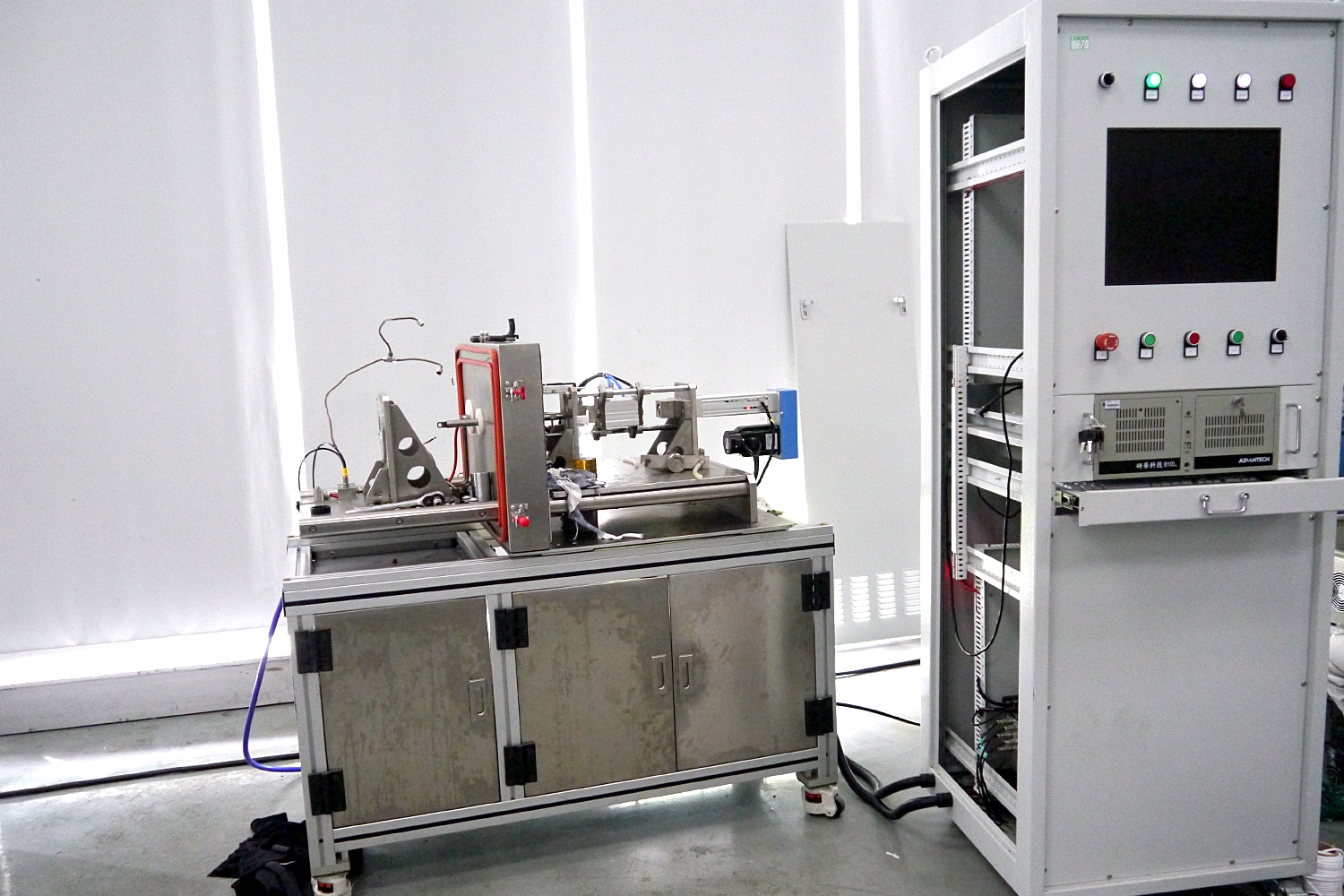

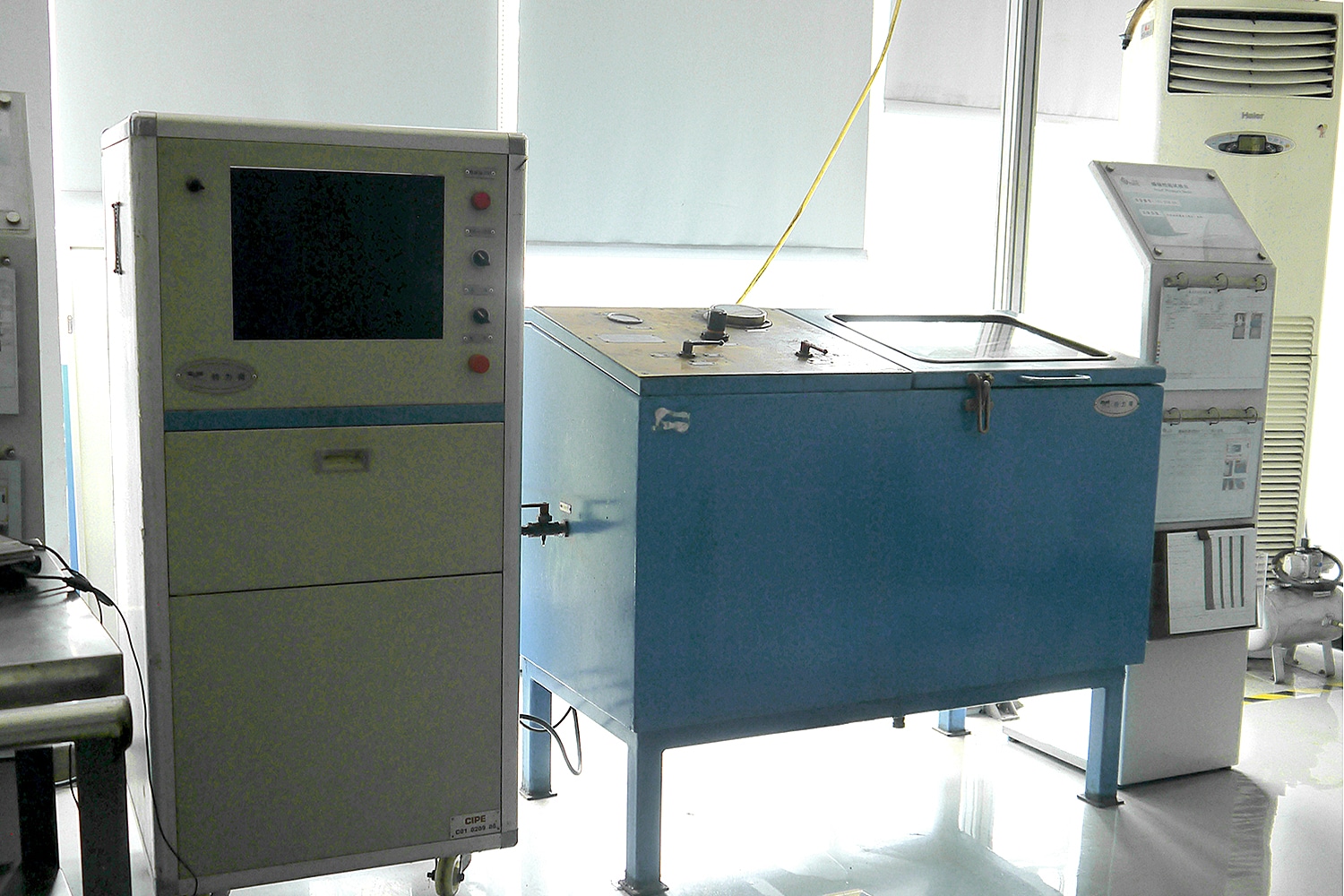

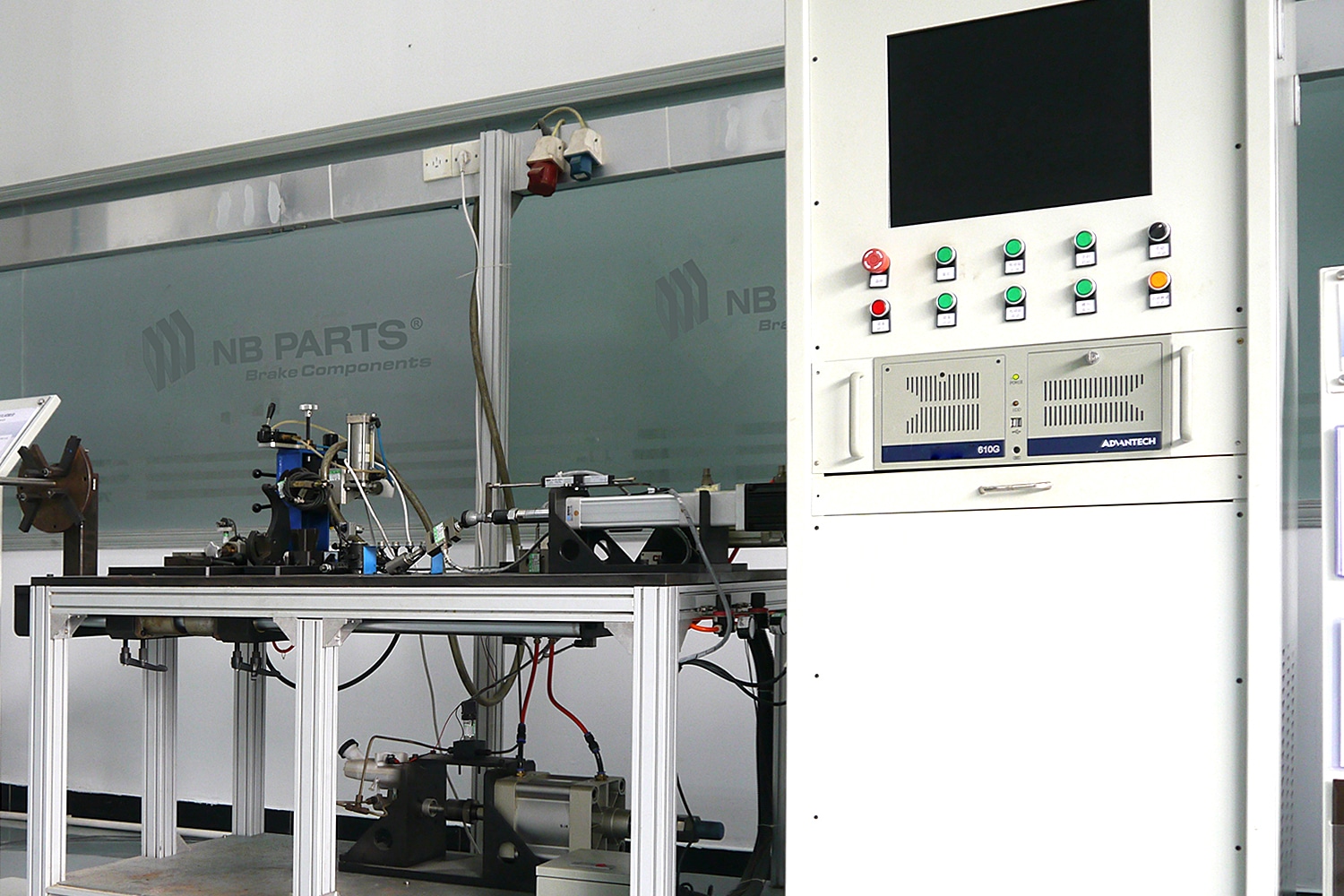

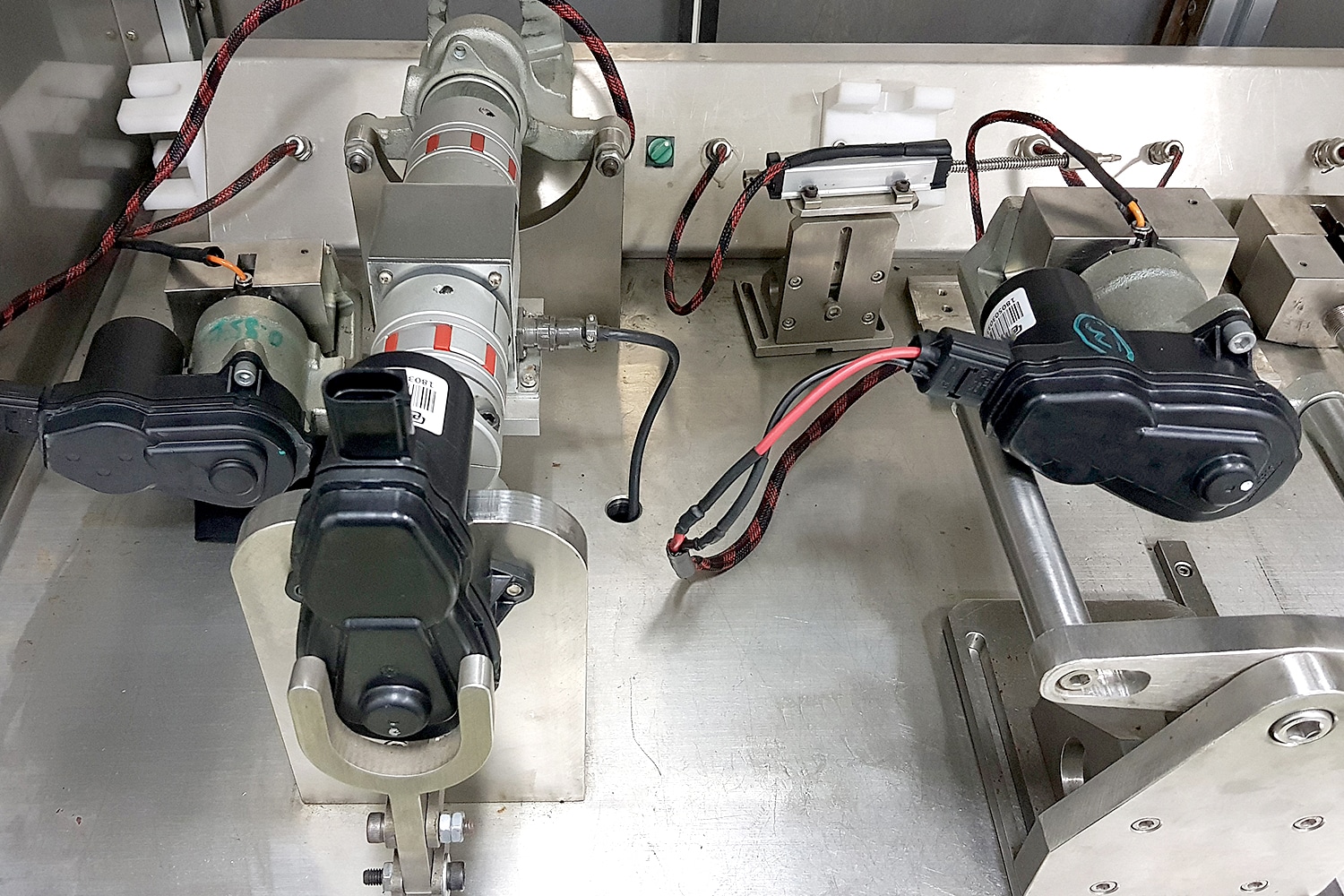

test machines

With a variety of different test machines, we can test all functional parameters under real conditions.

(Life cycle, salt spray test, etc.)

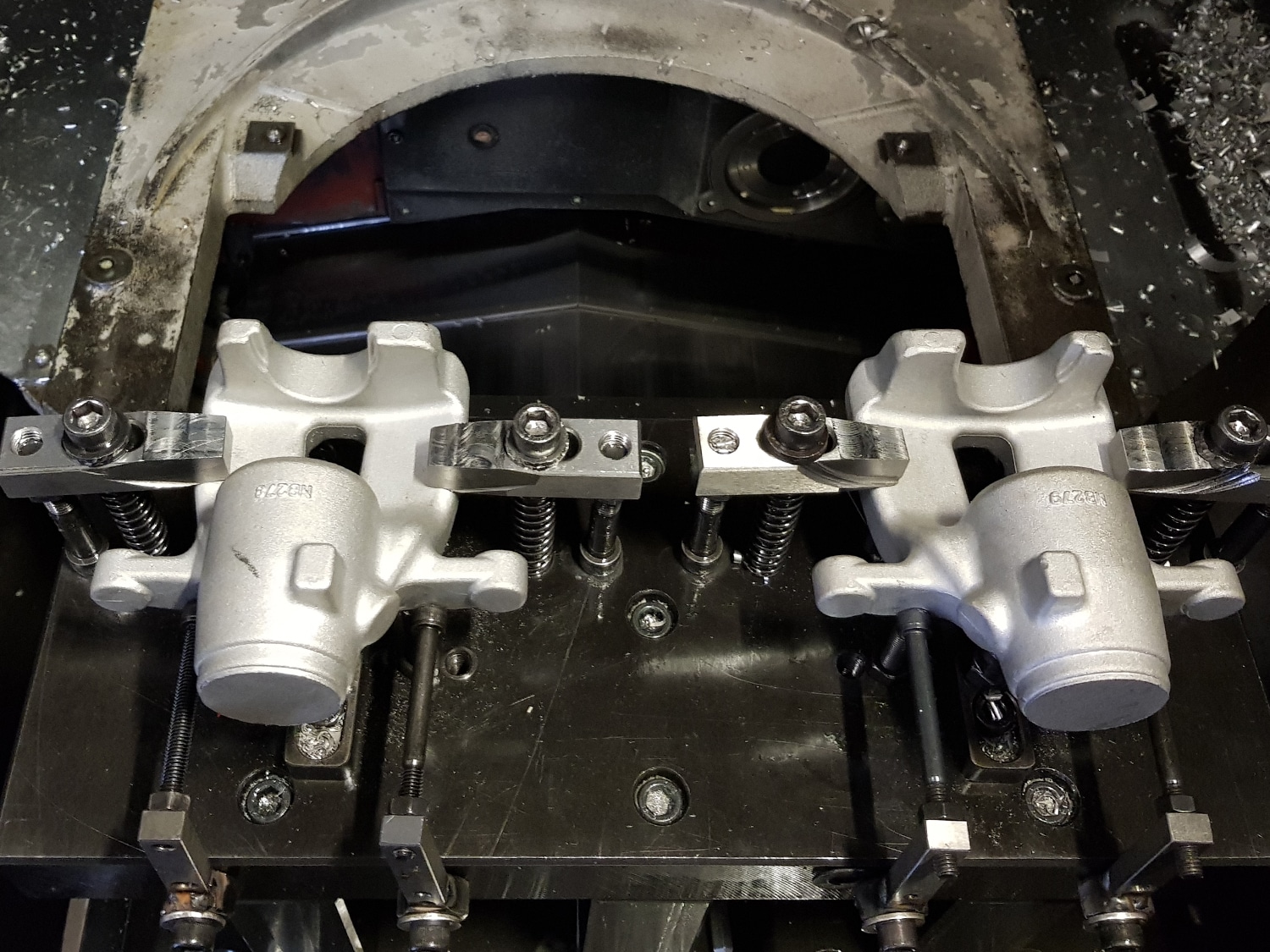

Permanent control of the production line

Permanent production control: After predetermined intervals, brake calipers are taken from the current production and tested according to our strict guidelines.

Monitoring of

all supply chains

The entire supply chain is a subject to constant control. Not only the raw materials, but also the supplier itself is audited to ensure a consistent quality in the OES.

Machine fleet at a glance

Complete validation processes

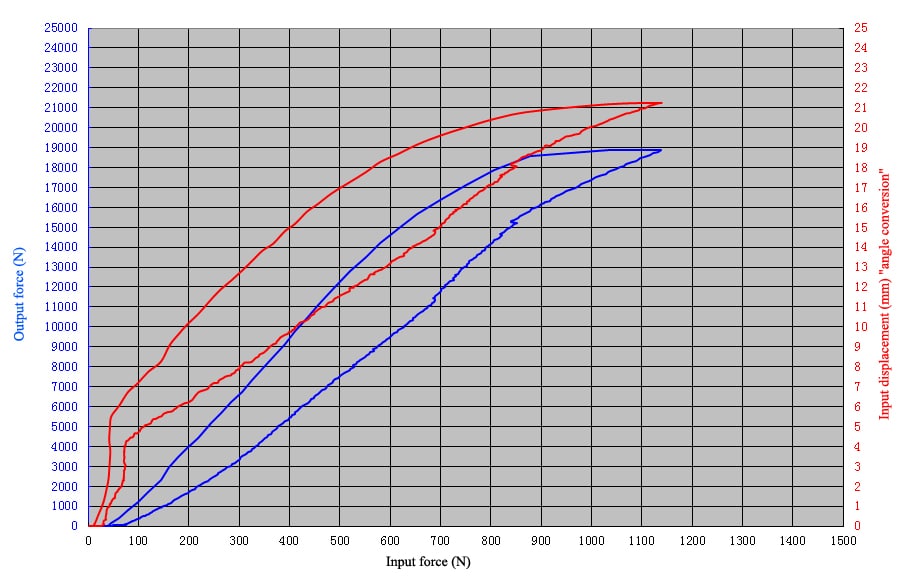

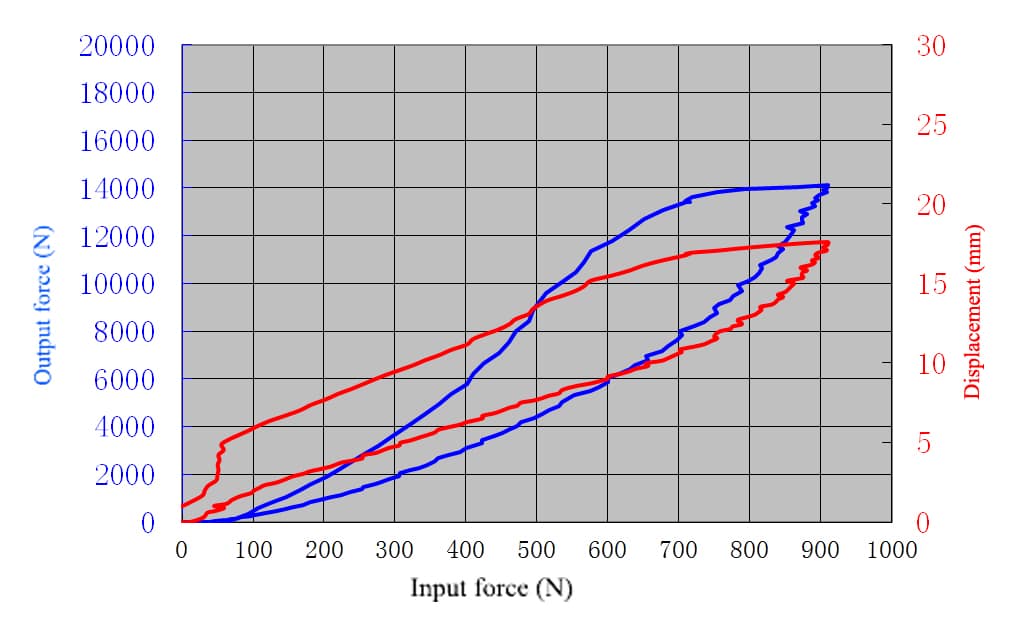

Comparison calipers NB & AM

The quality of our brake calipers is the key to our company‘s success. Therefore we constantly test different calipers on the market, thus we produce on highest standards by continuous quality management while simultaneously refine our products to your requirements and needs.

The diagrams below demonstrate the significant difference in quality of our calipers compared to common calipers.

Both – the brake force and the restistance – are consistently higher.

Continuous quality management ensures product safety

Comparison calipers NB & AM

The quality of our brake calipers is the key to our company‘s success. Therefore we constantly test different calipers on the market, thus we produce on highest standards by continuous quality management while simultaneously refine our products to your requirements and needs.

The diagrams below demonstrate the significant difference in quality of our calipers compared to common

calipers. Both – the brake force and the restistance – are consistently higher.

Our strictly controlled and constantly evolving quality management is essential for identifying flaws in the production process and to continuously optimize procedures in the manufacturing and sales department.

m.schindler@nb-parts.de | International sales manager | +49 (0) 9191 / 34 16 420

Fifteen years of experience in the automotive industry

My strengths: Structured approach to complex projects and a distinct ability to recognize important details early and take them into account without neglecting time, quality or budget requirements.

This allows me to meet the interface of service, development and production with the quality standards of our company and our customers.

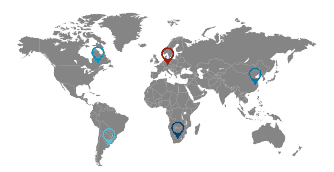

“My home is

the international trade market

in Original Equipment Service (OES)!”

the international trade market

in Original Equipment Service (OES)!”

With best regards

Michael Schindler

BRAKE CALIPER SPECIALIST

BRAKE CALIPER SPECIALIST